Warehouse ventilation

The warehouse is a room intended for the storage of material assets and for carrying out work with them. Warehouse ventilation provides climatic conditions that meet the standards of sanitation, hygiene, and manufacturability. Compliance with the conditions ensures the safety of the contents of the warehouse.

The difficulties that arise when finalizing the warehouse ventilation are due to the fact that the area is occupied by racks and mechanical devices are used to transport and move material assets.

Warehouse ventilation: requirements and types

Four categories of requirements, according to stored products:

1. Products: we are talking about precision instruments, certain steel grades, rolled non-ferrous metals, and electrical materials.

The product is expected to protect against:

- exposure to precipitation;

- overheating due to low temperatures;

- hypothermia as a result of high temperatures;

- temperature difference.

Cooled and insulated warehouses that are heated are considered.

2. Products: tin, cables, tools, paintwork materials, measuring instruments.

It is assumed that products are stored from low temperatures and precipitation.

Type of storage facilities: insulated heated.

3. Products: rubber, roofing felt, roofing material, leather.

It is assumed that it is required to protect valuables from overheating as a result of high temperatures and precipitation.

Warehouse type: insulated. Provides storage of products under refrigeration conditions.

4. Type of premises: not insulated under a canopy.

It is required to protect the product from possible precipitation.

Warehouse ventilation standards

At the stage of arranging the ventilation of a warehouse, it is recommended to rely on building codes and regulations: SNiP 31-04-2001 or SNiP 2.11.01-85 “Warehouse buildings”. In addition, the warehouse ventilation rules must comply with the standards provided for by the categories of products for which the warehouse is used for storage.

According to SNiP 2.11.01-85, the warehouse must be provided with natural general ventilation, providing a single air exchange per hour. For example, if the area of the warehouse is 5000 m2 and the height is 8 m, then the ventilation capacity is 40000 m3/h.

Consider, as an example, the rate of exchange of air flows for a warehouse of harmful substances:

Fuel and lubricants warehouse: hourly air exchange rate is 2.5–5 (if the staff stays at the warehouse permanently) or from 1.5–2 (if the staff stays temporarily).

Solvent rooms: 9-10 (staff in the room permanently) or 4-5 (staff in the room temporarily).

Warehouse of volatile substances: 2.5–5 or 1.5–2.

In the alcohol warehouse, the humidity should not exceed 85%. The temperature depends on the type of alcohol (from 0 to 30 °C).

Natural and forced ventilation

The natural ventilation of the warehouse must comply with the following rules:

The length of the horizontal section of the air outlet is more than 3 meters;

The air velocity must exceed 1 meter per second;

The shaft is responsible for the hood is located 1.5 m above the roof ridge.

Natural ventilation is easy to maintain. But it has a drawback: its efficiency directly depends on wind speed and air temperature. Natural ventilation is not able to cope with the task of cleaning, humidifying and warming the air.

In this regard, they resort to forced ventilation of warehouses. Forced ventilation is carried out through the use of electric fans. This equipment provides ventilation of warehouses, regardless of the time of year and weather.

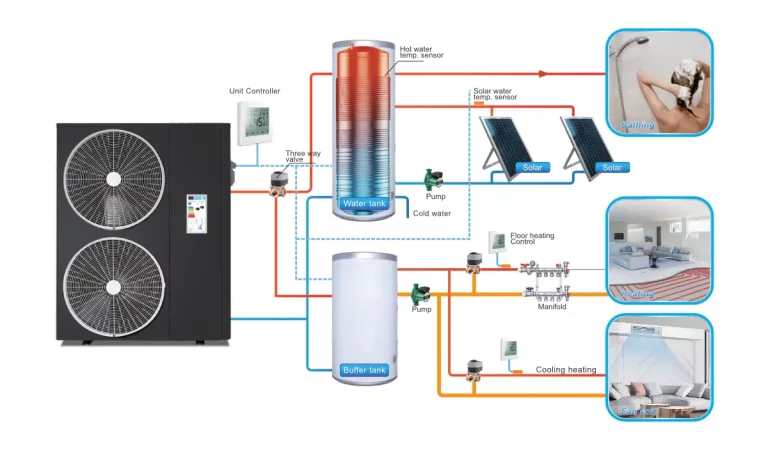

Alternative energy sources for warehouse ventilation

Forced ventilation of a warehouse can be provided not only by a mechanical system of fans powered by electricity. Growing share use of alternative energy sources(solar, wind). The main advantages of this method are:

- no need to use electricity, which reduces costs;

- general availability and inexhaustibility of the resource (the ability to use this source of energy all year round).

Buy a solar collector for warehouses