Solar collectors for heating water And Air – What is it? What are they needed for?

Solar Collector is a device for collecting the thermal energy of the Sun (solar plant), carried by visible light and near infrared radiation. Unlike solar panels that produce electricity, the solar collector heats the heat-transfer material.

Usually used for the needs of hot water supply and space heating.

Types of solar collectors

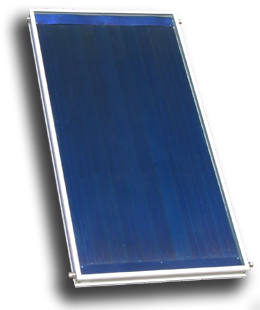

Flat plate collectors

A flat-plate collector consists of an element that absorbs solar radiation (absorber), a transparent coating and a thermally insulating layer. The absorber is connected to the heat transfer system. It is coated with black paint or a special selective coating (usually black nickel or titanium oxide sputtering) to increase efficiency. The transparent element is usually made of tempered glass with reduced metal content or a special corrugated polycarbonate. The back of the panel is covered with a heat-insulating material (eg polyisocyanurate). The tubes through which the coolant is distributed are made of cross-linked polyethylene or copper. The panel itself is airtight, so the holes in it are closed with silicone sealant.

In the absence of heat intake (stagnation), flat-plate collectors are able to heat water up to 190-210 °C.

The more incident energy is transferred to the coolant flowing in the collector, the higher its efficiency. It can be increased by using special optical coatings that do not emit heat in the infrared spectrum.

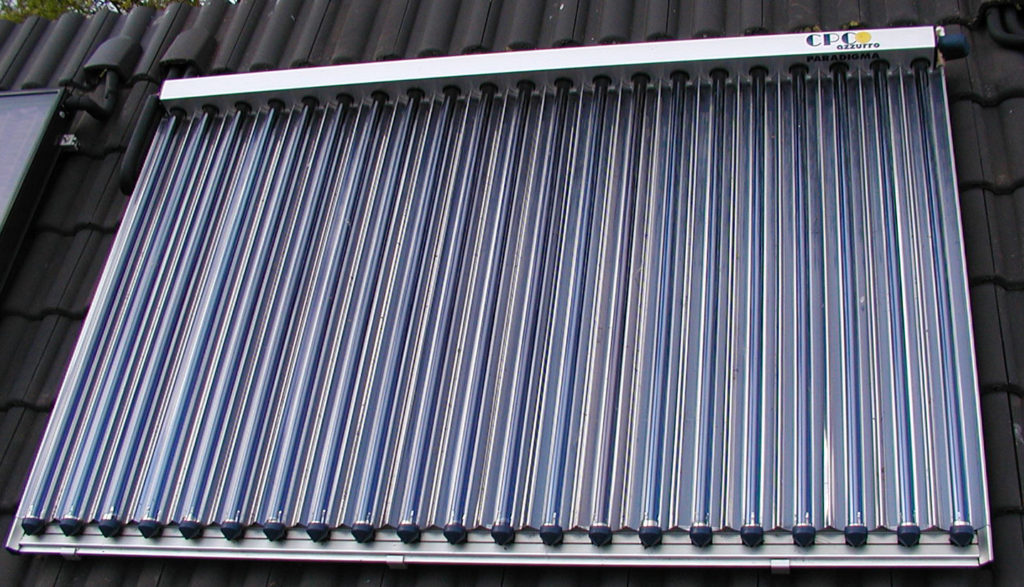

Vacuum

It is possible to increase the temperature of the coolant up to 250-300 °C in the heat extraction limitation mode. This can be achieved by reducing heat loss as a result of the use of a multi-layer glass coating, sealing or creating a vacuum in the collectors.

In fact, a solar heat pipe has a device similar to household thermoses. Only the outer part of the tube is transparent, while the inner tube has a highly selective coating that captures solar energy. There is a vacuum between the outer and inner glass tube. It is the vacuum layer that makes it possible to save about 95% of the captured thermal energy.

In addition, heat pipes have found application in vacuum solar collectors, which act as heat conductors. When the installation is irradiated with sunlight, the liquid in the lower part of the tube heats up and turns into vapor. Vapors rise to the top of the tube (condenser), where they condense and transfer heat to the collector. Using this circuit allows you to achieve greater efficiency (compared to flat collectors) when operating at low temperatures and low light.

Modern household solar collectors are able to heat water up to the boiling point even at negative ambient temperatures.

Household collector device

The coolant (water, air, oil or antifreeze) is heated by circulating through the collector and then transfers thermal energy to the storage tank, which accumulates hot water for the consumer.

In a simple variant, water circulation occurs naturally due to the temperature difference in the collector. This solution improves the efficiency of the solar installation, since the efficiency of the solar collector decreases with increasing coolant temperature.

There are also solar water heating installations of the storage type, in which there is no separate storage tank, and the heated water is stored directly in the solar collector. In this case, the installation is a tank close to a rectangular shape.

Advantages and disadvantages of flat and vacuum collectors

| Vacuum tubular | Flat highly selective |

| Advantages | Advantages |

| Low heat loss | Ability to clear snow and frost |

| Efficiency in the cold season up to -30C | High performance in summer |

| Ability to generate high temperatures | Excellent price/performance ratio for southern latitudes and warm climates |

| Long period of work during the day | Can be installed at any angle |

| Ease of installation | Lower initial cost |

| Low windage | |

| Excellent price/performance ratio for temperate latitudes and cold climates | |

| Disadvantages | Disadvantages |

| Inability to self-clear snow | High heat loss |

| Relatively high initial project cost | Poor performance during the cold season |

| Working angle of inclination not less than 20° | The complexity of installation associated with the need to deliver the assembled collector to the roof |

| High windage |

Solar collectors-concentrators

An increase in operating temperatures up to 120–250 °C is possible by introducing concentrators into the solar collectors using parabolic trough reflectors laid under the absorbing elements. Solar tracking devices are required to obtain higher operating temperatures.

Solar air collectors

Solar air collectors are devices that work on solar energy and heat the air. Solar air collectors are most often used for space heating, and drying agricultural products. Air passes through the absorber due to natural convection or under the influence of a fan.

In some solar air heaters, fans are attached to the absorber plate to improve heat transfer. The disadvantage of this design is that it consumes energy to operate the fans, thus increasing the operating costs of the system. In cold climates, the air is directed into the gap between the absorber plate and the insulated back wall of the collector: thus, heat loss through the glazing is avoided. However, if the air is heated no more than 17°C above the outside air temperature, the heat transfer medium can circulate on both sides of the absorber plate without much loss of efficiency.

The main advantages of air collectors are their simplicity and reliability. With proper care, a quality collector can last 10-30 years and is very easy to manage. A heat exchanger is not required as the air does not freeze.

Application

Solar collectors are used for heating industrial and domestic premises, for hot water supply of production processes and for household needs. The largest number of production processes that use warm and hot water (30-90 °C) take place in the food and textile industries, which thus have the highest potential for the use of solar collectors.

In Europe in 2000, the total area of solar collectors was 14.89 million m², and worldwide – 71.341 million m².

Concentrator solar collectors can produce electricity using photovoltaic cells or a Stirling engine.

Solar collectors can be used in seawater desalination plants. According to the German Aerospace Center (DLR), by 2030 the cost of desalinated water will drop to 40 euro cents per cubic meter of water.

In Russia

According to JIHT RAS research, during the warm period (from March-April to September), in most of Russia, the average daily amount of solar radiation is 4.0-5.0 kWh/m² (in the south of Spain – 5.5-6.0 kWh/ m², in the south of Germany – up to 5 kWh / m²). This makes it possible to heat about 100 liters of water for domestic purposes using a 2 m² solar collector with a probability of up to 80%, that is, almost daily. In terms of the average annual influx of solar radiation, the leaders are Transbaikalia, Primorye and the South of Siberia. They are followed by the south of the European part (up to approximately 50º N) and a significant part of Siberia.

The use of solar collectors in Russia is 0.2 m² / 1000 people. In Germany, 140 m² / 1000 people are used, in Austria 450 m² / 1000 people, in Cyprus about 800 m² / 1000 people.

In the summer period, most regions of Russia up to 65º north latitude are characterized by high values of average daily radiation. In winter, the amount of incoming solar energy decreases several times depending on the latitudinal location of the installation.

For all-season use, the units must have a large surface area, two antifreeze circuits, and additional heat exchangers. In this case, evacuated collectors or flat-plate collectors with a highly selective coating are used, since the temperature difference between the heated coolant and the outside air is greater. However, this design is more expensive.

The construction of collectors is currently carried out mainly in the Krasnodar Territory, Buryatia, Primorsky and Khabarovsk Territories.

Solar towers

For the first time, the idea of creating an industrial-type solar power plant was put forward by the Soviet engineer N.V. Linitsky in the 1930s. At the same time, he proposed a scheme for a solar station with a central receiver on the tower. In it, the system for capturing the sun’s rays consisted of a field of heliostats – flat reflectors controlled in two coordinates. Each heliostat reflects the rays of the sun onto the surface of the central receiver, which is raised above the field of heliostats to eliminate the influence of mutual shading. In terms of its dimensions and parameters, the receiver is similar to a conventional steam boiler.

Economic evaluations have shown the feasibility of using large 100 MW turbine generators at such stations. For them, typical parameters are a temperature of 500 °C and a pressure of 15 MPa. Taking into account losses, a concentration of about 1000 was required to provide such parameters. Such a concentration was achieved by controlling heliostats in two coordinates. The stations had to have heat accumulators to ensure the operation of the heat engine in the absence of solar radiation.

Since 1982, several tower-type plants have been built in the United States with a capacity of 10 to 100 MW. A detailed economic analysis of systems of this type showed that taking into account all the costs of construction, 1 kW of installed capacity costs approximately $1150. One kWh of electricity costs about $0.15.

Parabolic trough concentrators

Parabolic-cylindrical concentrators have the shape of a parabola stretched along a straight line.

In 1913, Frank Schumann built a pumping station in Egypt from parabolic trough concentrators. The station consisted of five hubs each 62 meters long. Reflective surfaces were made from ordinary mirrors. The station produced steam, with which it pumped about 22,500 liters of water per minute.

A parabolic-cylindrical mirror concentrator focuses solar radiation into a line and can provide its hundredfold concentration. A tube with a coolant (oil) or a photovoltaic cell is placed at the focus of the parabola. The oil is heated in a tube to a temperature of 300-390 °C. In August 2010, NREL tested SkyFuel’s installation. During the tests, the thermal efficiency of parabolic trough concentrators was demonstrated to be 73% at a coolant heating temperature of 350 °C.

Parabolic cylindrical mirrors are made up to 50 meters long. Mirrors are oriented along the north-south axis and arranged in rows every few meters. The coolant enters the heat accumulator for further generation of electricity by a steam turbine generator.

From 1984 to 1991, nine power plants were built from parabolic trough concentrators in California with a total capacity of 354 MW. The cost of electricity was about $0.12 per kWh.

The German company Solar Millennium AG is building a solar power plant in Inner Mongolia (China). The total capacity of the power plant will increase to 1,000 MW by 2020. The capacity of the first stage will be 50 MW.

In June 2006, the first thermal solar power plant with a capacity of 50 MW was built in Spain. In Spain, by 2010, 500 MW of power plants with parabolic trough concentrators can be built.

The World Bank is financing the construction of similar power plants in Mexico, Morocco, Algeria, Egypt and Iran.

The concentration of solar radiation allows to reduce the size of the photovoltaic cell. But at the same time, its efficiency decreases, and some kind of cooling system is required.

Parabolic concentrators

Parabolic concentrators are shaped like a paraboloid of revolution. The parabolic reflector is controlled in two coordinates when tracking the sun. The energy of the sun is focused on a small area. Mirrors reflect about 92% of the solar radiation falling on them. At the focus of the reflector, a Stirling engine, or photovoltaic cells, is fixed on a bracket. The Stirling engine is positioned so that the heating area is in the focus of the reflector. The working fluid of a Stirling engine is usually hydrogen or helium.

In February 2008, Sandia National Laboratory achieved an efficiency of 31.25% in a setup consisting of a parabolic concentrator and a Stirling engine.

Plants with parabolic concentrators with a capacity of 9–25 kW are currently under construction. Domestic installations with a capacity of 3 kW are being developed. The efficiency of such systems is about 22-24%, which is higher than that of photovoltaic cells. Collectors are made from common materials: steel, copper, aluminum, etc. without the use of “solar-grade” silicon. In metallurgy, the so-called “metallurgical silicon” with a purity of 98% is used. For the production of photovoltaic cells, “solar-grade” or “solar-grade” silicon with a purity of 99.9999% is used.

In 2001, the cost of electricity generated in solar collectors was $0.09-0.12 per kWh. The US Department of Energy predicts that the cost of electricity produced by solar concentrators will drop to $0.04-0.05 by 2015-2020.

Stirling Solar Energy develops solar collectors of large sizes – up to 150 kW with Stirling engines. The company is building the world’s largest solar power plant in southern California. By 2010 there will be 20,000 parabolic collectors with a diameter of 11 meters. The total capacity of the power plant can be increased up to 850 MW.

Fresnel lenses

Fresnel lenses are used to concentrate solar radiation on the surface of a photovoltaic cell or on a heat transfer tube. Both annular and waist lenses are used. In English, the term LFR is used – linear Fresnel reflector.

Distribution

In 2010, 1,170 MW of solar thermal power plants were operating worldwide. Of these, Spain has 582 MW and the US 507 MW. It is planned to build 17.54 GW of solar thermal power plants. Of these, in the USA 8670 MW, in Spain 4460 MW, in China 2500 MW. In 2011, there were 23 manufacturers and suppliers of flat collectors from 12 countries; 88 manufacturers and suppliers of vacuum manifolds from 21 countries.