Mold in an industrial building

A microscopic fungus that grows on walls, floors, ceilings in residential and industrial premises is mold. If in nature mold colonies perform important and useful functions, then mold in an industrial building is unacceptable. Its growth disrupts the technological process, creates unfavorable working conditions, and leads to a deterioration in product quality.

There are hundreds of types of mold, but for greater convenience, all the diversity is divided into three categories according to human impact: allergic mold, pathogenic and toxic mold. The last category is the most dangerous. Its representatives release mycotoxins into the air, they disrupt the normal metabolism in tissues. Possible consequences depend on the concentration of mycotoxins, from simple headache and nausea to pulmonary edema and death.

The appearance of mold in industrial premises: where does it come from?

Mold develops from microscopic spores present in water, soil, and air. But for growth to begin, spores must enter a favorable environment. Heat, humidity, stagnant air masses are the most attractive conditions for the development of mold. Therefore, its appearance is usually associated with insufficient ventilation and high humidity.

Where does mold come from in an industrial building? Another common cause: freezing of workshops. If they do not have heating or it is insufficient, in the cold season the walls and floor freeze through, and with the onset of a thaw, they thaw. Excess moisture is formed, impregnating thermal insulation, building materials. And mold starts to grow in them. Therefore, even if the premises are not used during the cold season, they are not allowed to freeze.

Two more reasons why mold appeared in an industrial building is insufficient waterproofing with a close occurrence of groundwater or a leaking pipeline. Whatever the root cause, if the workshop is warm and dry, the fungus will not appear in it.

Consequences of mold growth in industrial premises:

- violation of sanitary and hygienic working conditions;

- creation of an environment hazardous to the health of workers and the risk of developing acute poisoning;

- loss of energy efficiency of the facility;

- reducing the life of the building;

- violation of the technological process;

- damage to raw materials and related financial losses;

- violation of the conditions of storage of finished products, damage to its presentation.

Mold in industrial premises: how to get rid of it?

There are two methods of influencing the mold colony: mechanical and chemical. Usually they are used together: first they clean the walls and floor from the fungus, and then the affected areas are additionally treated with chemicals. But if the mold has spread to several rooms, the whole building is affected by it, these measures are not enough. Even after the elimination of the main colonies, there will be many spores that will begin to germinate again. In this case, it is necessary to completely disinfect the room, for example, using zonation.

When answering the question of how to get rid of mold in an industrial building, it is important to understand how to prevent its reappearance. To do this, eliminate excess moisture, stagnant air zones and cold points. Electric dehumidifiers can be used, but their use in production shops has its drawbacks. The devices operate in a limited area, and if the workshop is spacious, many dehumidifiers will have to be installed, which entails high financial costs. In addition, they run on expensive electricity, increase the load on the power grid, and create the risk of a short circuit during power surges.

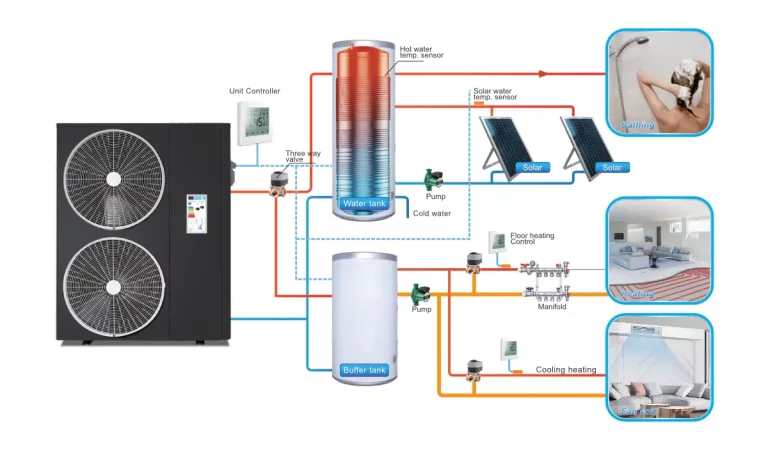

Creating ventilation and heating that maintain a healthy microclimate is the least expensive way to prevent mold in an industrial building. Solar-powered equipment can be used to upgrade existing systems.

- Suitable for installation in rooms of any size.

- Does not require a connection to the mains.

- Does not consume expensive energy sources (gas, coal, diesel).

- Environmentally friendly and safe for humans and the environment.

- Provides protection against mold in an industrial environment.

Solar energy for industrial premises mold protection

The principle of operation of solar equipment is simple. The sun’s rays heat the air entering the device and at the same time remove excess moisture from it. With the help of a fan, the prepared air masses are fed into the premises, where they begin to circulate and give off heat to the floor and walls. A positive temperature and a healthy microclimate are established in the workshop. The stale air is removed through the ventilation openings.

When the equipment is powered by solar energy, the positive temperature in the room is maintained even in the cold season. Therefore, with its help it is easy to create an efficient heating system that does not require any additional costs. The problem with freezing of workshops will be solved, and the risk of mold development, for this reason, will be eliminated.

Mold in industrial premises appears quickly, but getting rid of it is problematic. It is much easier to prevent the formation of fungus by creating efficient solar-powered ventilation and heating systems.

Get rid of mold in an industrial building