Issues of organizing local ventilation in buildings for various purposes

Local ventilation devices remove polluted air from the points of its formation (exhaust version) or supply fresh air (supply air). They are often used in production environments, as well as in kitchens.

Varieties of local ventilation systems

The modern industry offers a wide range of equipment for supply and exhaust local ventilation in residential and industrial premises.

Local supply

The organization of a local supply ventilation system does not require significant financial investments, labor-intensive installation, and maintenance. Most often, it is used to ventilate industrial premises with increased harmfulness (for example, when a large number of gases and hazardous chemical elements are released) and is sold in various versions.

- The principle of operation of the local ventilation system according to the type of air oases involves separating the area of the internal space of the building by means of movable partitions about 2-2.5 m high for supplying cooled air jets.

- Air curtain – created using fan heaters installed near windows, doors, or stoves.

- Air shower – the organization of an active high-speed influx of purified fresh air. The technology allows ensuring the good circulation of air masses throughout the room due to their mixing.

Local exhaust

Significant indicators of harmfulness or increased formation of foreign odors and humidity (as happens in the kitchen) require the use of local exhaust ventilation, designed to remove exhaust air masses from a limited area in the building. There are specialized suction systems for removing gases and soot, smoke and dust pollution.

- Onboard suctions are open-type mechanisms designed to neutralize hazardous compounds by massive removal of exhaust air masses.

- Semi-open exhausts are ventilation systems, examples of which are fume hoods and umbrellas. Before selecting and installing such structures, calculations should be made to determine whether their power corresponds to the volume of air that needs to be removed.

- Local exhaust systems do not allow toxic substances to enter the main part of the space of the room and are able to ensure compliance with the sanitary and technical standards of working conditions in the organization at a high level.

There are certain rules and requirements for the installation and operation of local exhaust ventilation at work:

- production facilities where gases and other harmful compounds accumulate must be hermetically sealed;

- hazardous substances must be drawn out of the room according to the path determined by their natural properties (tendency to settle or high volatility);

it is necessary to comply with the dimensions of the equipment established by regulatory documents, otherwise, the local ventilation system of the workplace may interfere with the performance of their duties by employees.

Free organization of autonomous local ventilation systems

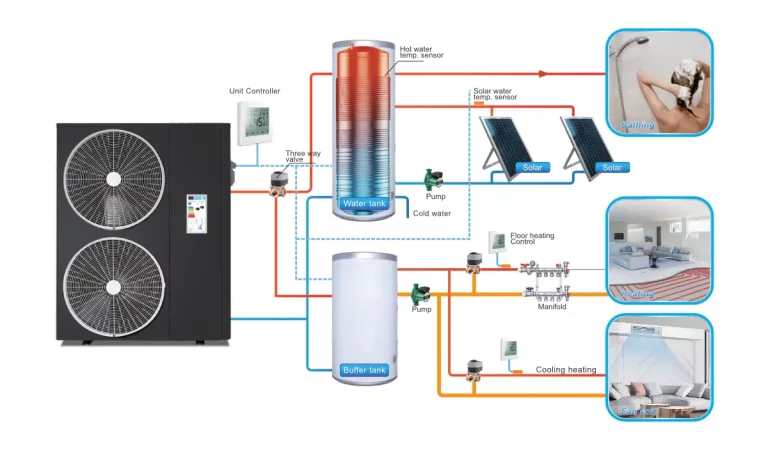

Air collectors, used for organizing local ventilation in buildings, allow you to create autonomous and economical systems. Solar energy is free and does not depend on the availability and uninterrupted operation of electrical networks.

Solar Fox equipment is easy to install and provides automatic air renewal in the room. It can be used as the main or additional ventilation system, depending on the characteristics of the room and the requirements for the intensity of its air exchange.

Additional advantages of systems based on solar panels include their fire safety and the ability to deal with excess humidity in rooms, drying and warming them up as needed. This is an environmentally friendly and affordable equipment that pays for itself in a short time during operation.